Published on October 31, 2017

For the most part, fingerprint capture systems attempt to emulate the same mechanical process that was used at the turn of the century – the twentieth century. The process is extremely mechanical in nature and is prone to human error and human mechanical limitations. The old standard FBI methodology of rolling ringers out and thumbs in, or going from a point of most resistance to least resistance in has morphed into “rock and roll” and other fingerprint capture techniques. In many cases live scan systems use commonly available hardware components but it is the software where we see differences between systems.

Each system obtains and acquires data that will fill each of the fields required by a NIST record. In the case of fingerprints, each rolled fingerprint occupies a space that is 1.6 inches (max) in width and 1.5 inches in height (max). The technician will attempt to place the core (center) of the fingerprint in the center of the box as well as placing the distal flexion crease at the base of the image. They will then commence the capture of the person’s finger detail by filling the box, as best as possible.

During the ink and paper era, technicians were taught to roll the finger from nail edge to nail edge. In other words, 90° to 90° a full 180° of friction skin. The pivot point of the person being printed was at the shoulder and not the elbow or wrist. That process ensured a maximum rotation which resulted in a complete fingerprint. Unfortunately, that is not what is happening today. I spent some time in a booking facility watching people being processed and in almost each case, I saw that the rotation of the digits during the acquisition process was approx. 45° to 45°. Less than half of the available friction ridge detail on a digit was being captured. The image on the screen looked reasonable, the box was almost filled, but more than half of the friction ridge detail was missing. The following illustrates the problem.

Here is a typical rolled fingerprint.

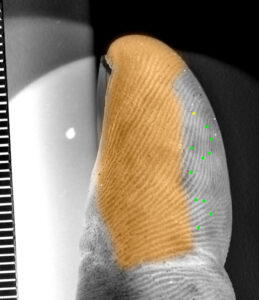

Here is a photo of the same finger.

The friction ridge detail in the orange region was not captured in the rolled fingerprint image

As latent print examiners we know that the detail on the edge of a finger as well as the tip of a finger can be crucial in assisting with a confident evaluation in a comparison process. Not acquiring this information raises the specter of a false exclusion determination which can be catastrophic.

In addition to the previous issue, I have also seen technicians struggling with the software and hardware of a live scan system. People really do come in all shapes and sizes, including technicians. Tall people tend to have a higher arm angle when being processed for prints as compared to shorter people such as children. Yet, there is no real way to reconcile those angles with a fixed platform system. In some cases, the deposition pressure required by live scan systems along with the high rejection rates can be physically and mentally exhausting. I’ve personally observed high levels of absenteeism associated to the use of such live scan systems.

Ink and paper print processing also suffered from many inherent problems. In the book, Scott’s Fingerprint Mechanics by Robert D. Olsen Sr. He identifies the numerous errors possible when taking fingerprints, many of which, were as a result of not understanding the mechanics of fingerprint acquisition. Fingerprint acquisition using both the ink and paper method and live scan processing can cause artifacting, which is an unfortunate by-product of trying to create a two-dimensional image with a three-dimensional object. Artifacting is increased when a finger is not rolled in a constant and unrestricted manner.

So how do we solve these and other problems inherent with the mechanical acquisition of fingerprints and palm prints? I think the best way forward is to stop thinking about the current acquisition methods in favor of developing technologies that process the hands differently. I am an advocate of acquiring the friction ridge detail on a hand in a manner that requires virtually no effort by the person being processed or by the technician processing the individual. A hand is placed in a cradle and, beep, the data is acquired. The envisioned process should be much quicker than current processing times, which requires each NIST fingerprint, finger phalange, or palm print element be created one at a time, and I believe it will create more reliable and useful records. It will also go a long way to reduce the absenteeism and stress that some live scan systems create.

I have seen one contact-less system currently being produced and I feel there is some promise inasmuch we are finally moving in the right direction, away from the mechanical process. The system I saw produced “flat” like fingerprint images, but I’m sure it wouldn’t take much more to get to the goal of a three-dimensional record of all the friction skin on the hand. For many years, people have had to wrestle with technology. We’ve created “workarounds” ad nauseum, but here in 2017 its time technology started living up to its initial promise. It should be working for us, not us working for it.

Shane Turnidge

www.sstforensics.com